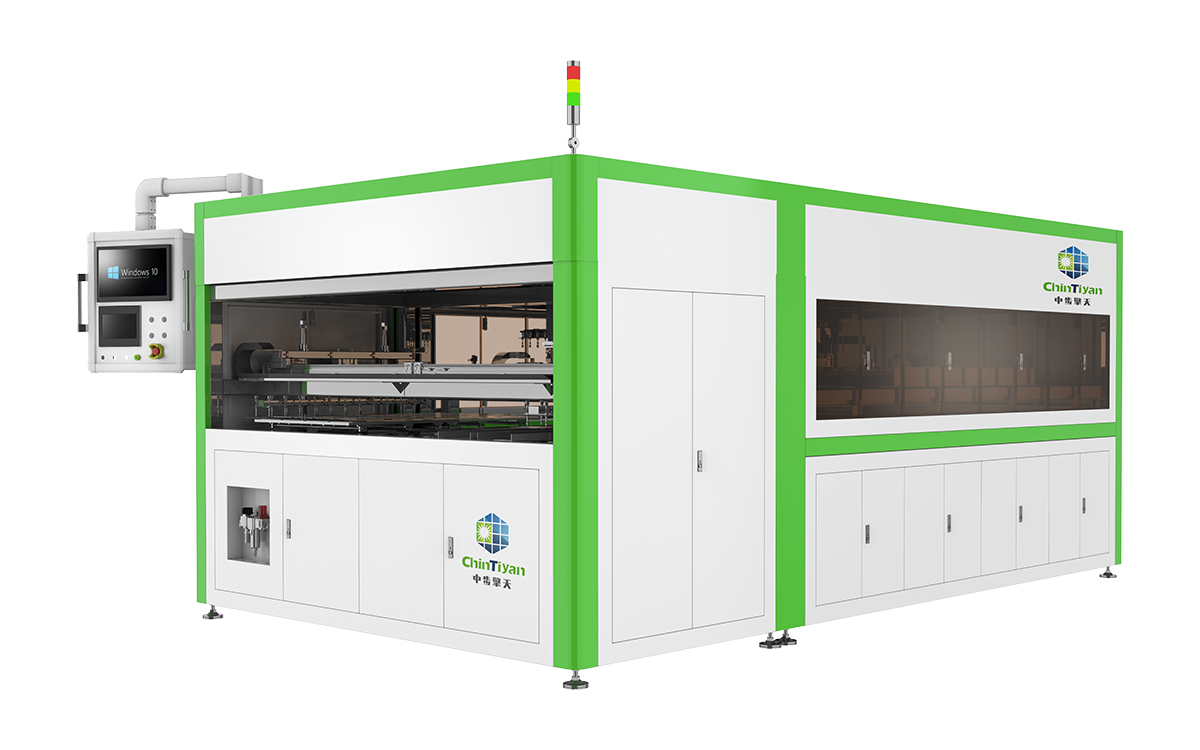

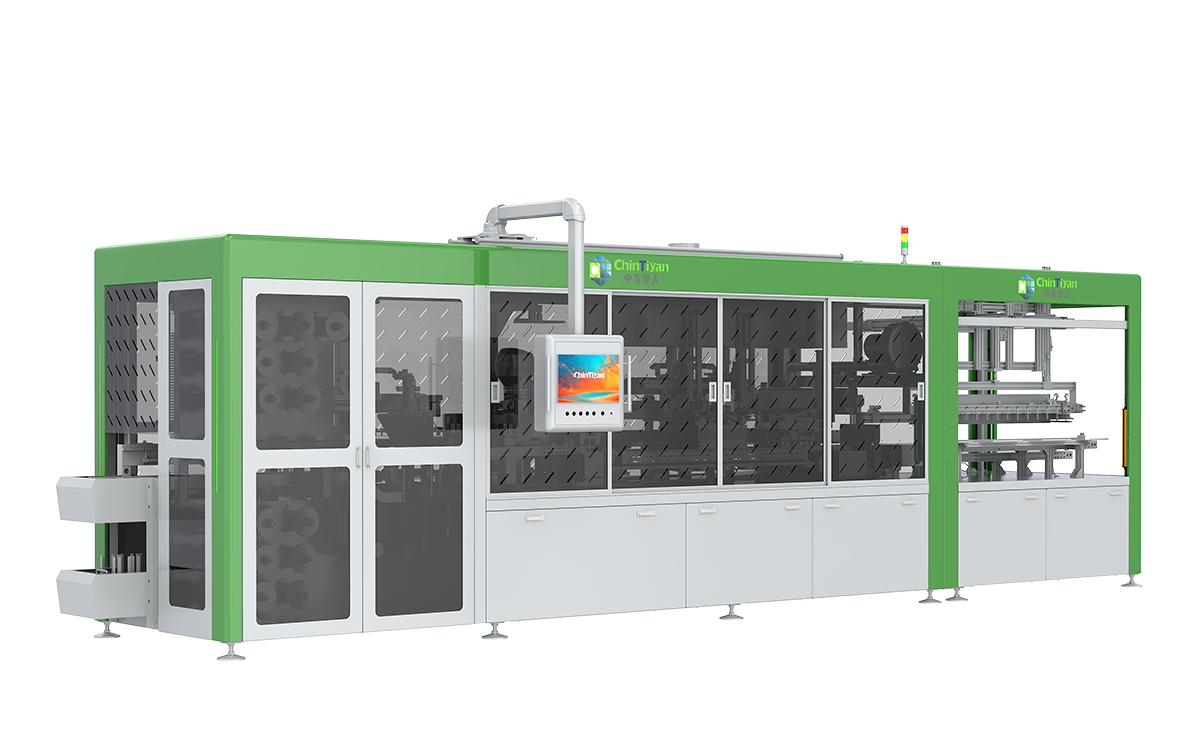

Auto Bussing Machine

Classification:

The bussing machine is the process of welding the solar cell strings produced by the string welding machine together with busbars to achieve the effect of concentrating the power generation current of each cell.

Contact:

Details Introduction

The bussing machine is the process of welding the solar cell strings produced by the string welding machine together with busbars to achieve the effect of concentrating the power generation current of each cell.

Parameter

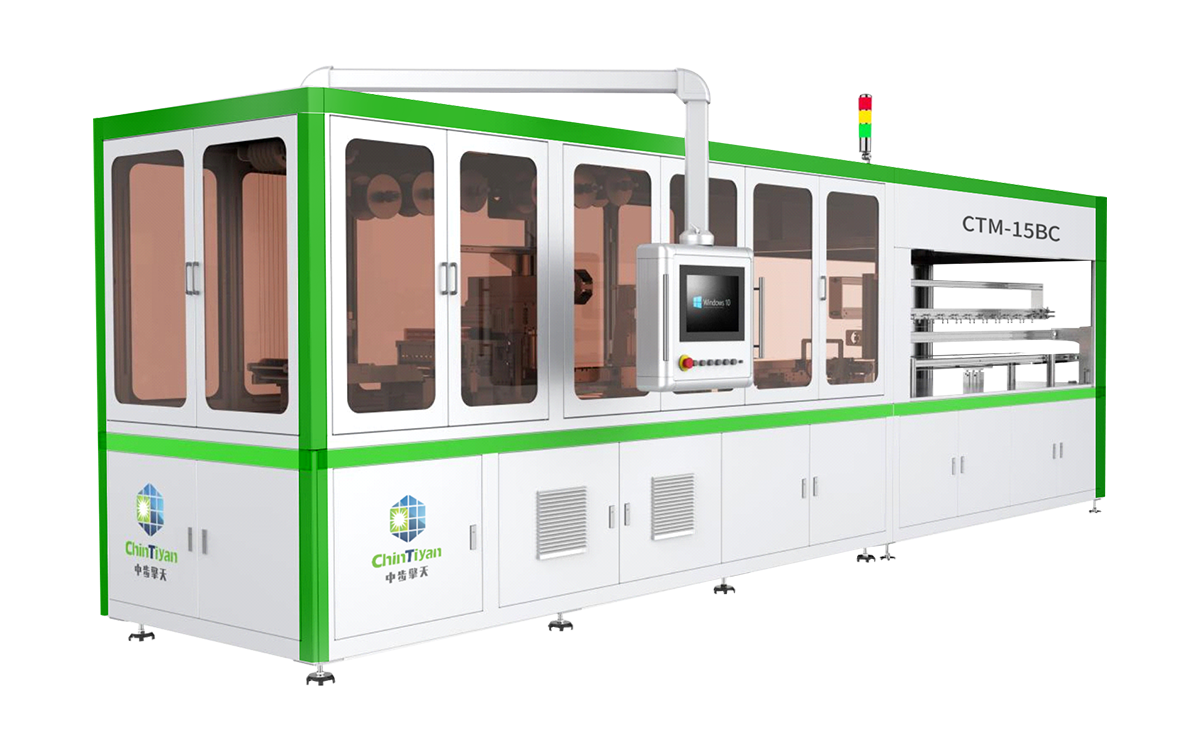

Equipment Specifications

| Product Model | Bussing Machine CT-HLH-200 |

| Beats | ≤18S |

| Activation Rate | 99% or higher |

| Overall Yield | ≥99%(according to the component unit, the componentlayout accuracy of the inflow bushing belt weldingmachine should be within ±0.5mm) |

| Fragmentation Rate | < 0.02%(in pieces) |

| Maximum Compatible Component Size | 1650*900-2500*1500mm |

| Compatible Cell size(mm) | Compatible 156-210mm |

| Compatible with Number of Grid Wire Roots | Compatible with 5-15 grids |

| Power supply | Three-phase five-wire 380V/220V 50/60Hz |

| Power | Peak 40KW Average about 20KW |

| Air Supply | Pressure 0.6-0.8MPa flow 2000L/min |

| Machine Size | 5220mmX2570mmX2450mm |

| Alarm Device | Tri-color light + buzzer |

| Deviation Correction | 9 camera visual positioning |

| Positioning Mechanism | Electric cylinder/servo module |

| Number of Anchor Points | ≥5 points |

| Positioning Method | Mechanical positioning |

| Feeding Method | Roll loading, automatic cutting, bending |

| Roll Size | Axle hole 20-25mm, outer diameter < 210mm |

| Roll Load Bearing | ≤13KG |

| Compatible Bustape Width | Factory supporting 4mm, 6mm |

| Compatible With Bustape Thickness | 0.18 mm to 0.4 mm |

| Cutting Accuracy | 0.5 mm or less |

| How the Lead Is Made | Bend straight up |

| Lead Angle and Deviation | 90。 Deviation of 2 to 3。 |

| Handling Method | Servo motor + vacuum adsorption |

| Positioning Mode | Mechanical positioning + vacuum adsorption |

| Positioning Accuracy | Less than 0.5mm |

| Distance From Busbar to Battery | 2-10mm adjustable |

| Busbar Overweld Strip Length | ≤2mm (length error) |

| Head Life | ≥1 year |

| Welding Head Replacement Time | ≤60min |

| Mode of Operation | Servo motor |

| Cooling Method | Air cooling |

| Welding Method | Electromagnetic induction welding |

| Number of welding Heads | 18 |

| Welding Head Control Method | Current control/time control |

| Welding Heating Time | ≤2s |

| Welding Temperature Control Accuracy | ± 5 ℃ |

| Welding Tension | Welding tension of welding strip ≥5N/mm (busbar and welding wire) |

| Weld Appearance | Molten tin full |

| Welding Contact Area | 80% or higher |

| Scar size | ≥(4*4)mm2 |

| Control Systems | PC+PLC (Reserve 5% of I/O points) |

| Communication Interface | Meet MES interconnection requirements |

Keyword:

Auto Bussing Machine

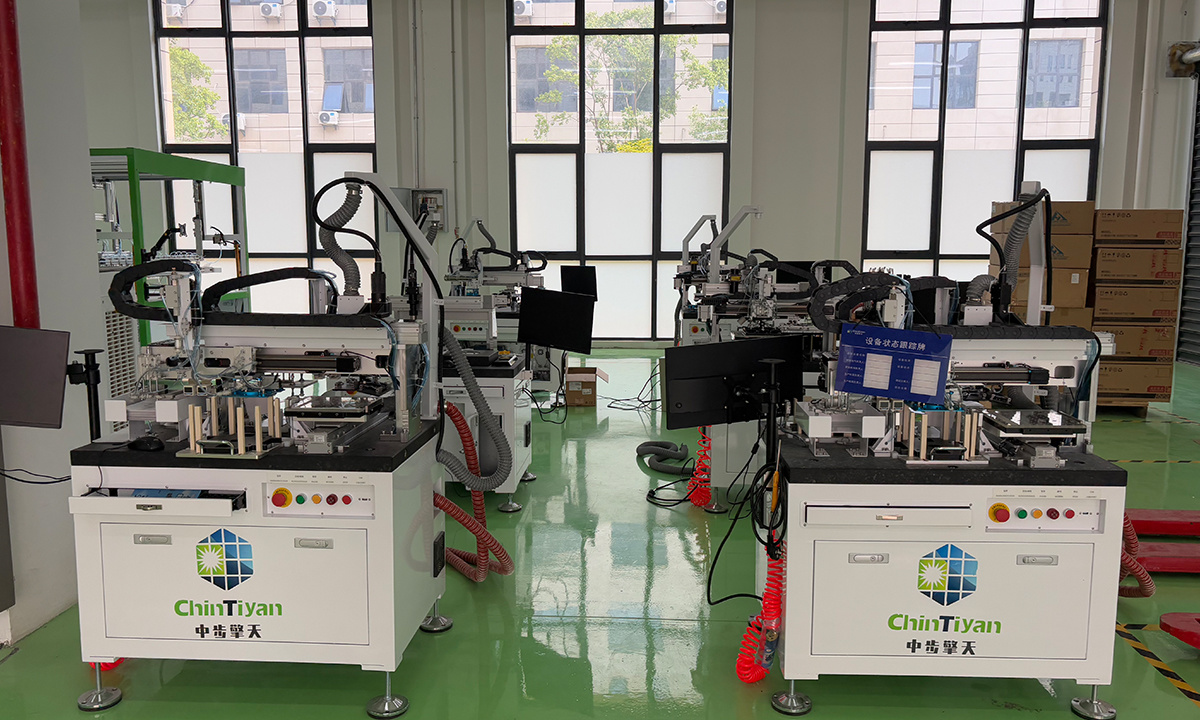

Production Strength

What is the Warranty Period of ChinTiyan New Energy?

1.One year standard warranty from the date of completion installation & commissioning for the Full/Semi-Automatic Solar PV Module Production Line, or 13 months from the date of shipment whichever is earlier.

2.For the BOM List of Raw Materials for Full/Semi-Automatic Solar Panel Production Line, the Warranty Period is usually Six Months, especially Flux, Heating Oil and some other Chemicals and Dangerous Materials.

3.Free warranty for One Year (including Labor and Material fees, excluding Man-made Damage). Any losses caused by human misuse, abuse or improper maintenance are not covered by the warranty. Maintenance fees will be charged appropriately outside the warranty period.

What are the Main Differences Between Full-Automatic and Semi-Automatic Solar PV Module Production Line?

1.For the Full-Automatic Solar PV Module Production Line, there are more Automatic Solar Machines and Equipment in the Production Line, which could surely save more labors.

2.In the Full-Automatic Solar PV Module Production Line, there are also many Automatic Conveyors and Transmission Lines, which could help to transfer the Raw Materials from one process to the next process; But in the Semi-Automatic Solar PV Module Production Line, it needs labors to carry the unfinished Solar PV Modules from one process to the next process.

What is the Payment Terms of the Purchasement in ChinTiyan?

1. Once the Clients confirm the Final Prices of all the solar making machines and equipment, ChinTiyan New energy will send the Performa Invoice (PI) to the Clients. Clients should arrange 40%T/T deposit as the Down Payment, then ChinTiyan factory will start manufacturing all the Machines and Equipment.

2. During the Manufacture Process, Clients can come to ChinTiyan factory to inspect all the Solar Machines and Equipment if required. After inspection, Clients should arrange the rest 60% Balanced Payment Before Delievery or Shipment. ChinTiyan factory start to pack all the Solar Machines and Equipment, and deliver them to Clients. If Clients could not come to China for the inspection, ChinTiyan factory could send the Videos and Photos of all the Solar Machines and Equipment for Clients as reference.

What is the Policy of Installation, Commissioning & Training Services of ChinTiyan New Energy?

1. Workers and Technical Engineers of the Purchaser can come to ChinTiyan’s factory to get the most Professional One-by-one Training.

2. ChinTiyan New Energy may also send Engineering Team to the Purchaser's factory to train their workers during operation.

3. Remote training through Internet tools like Team-Viewer, Google Meet or other instant communication software.

Related Products