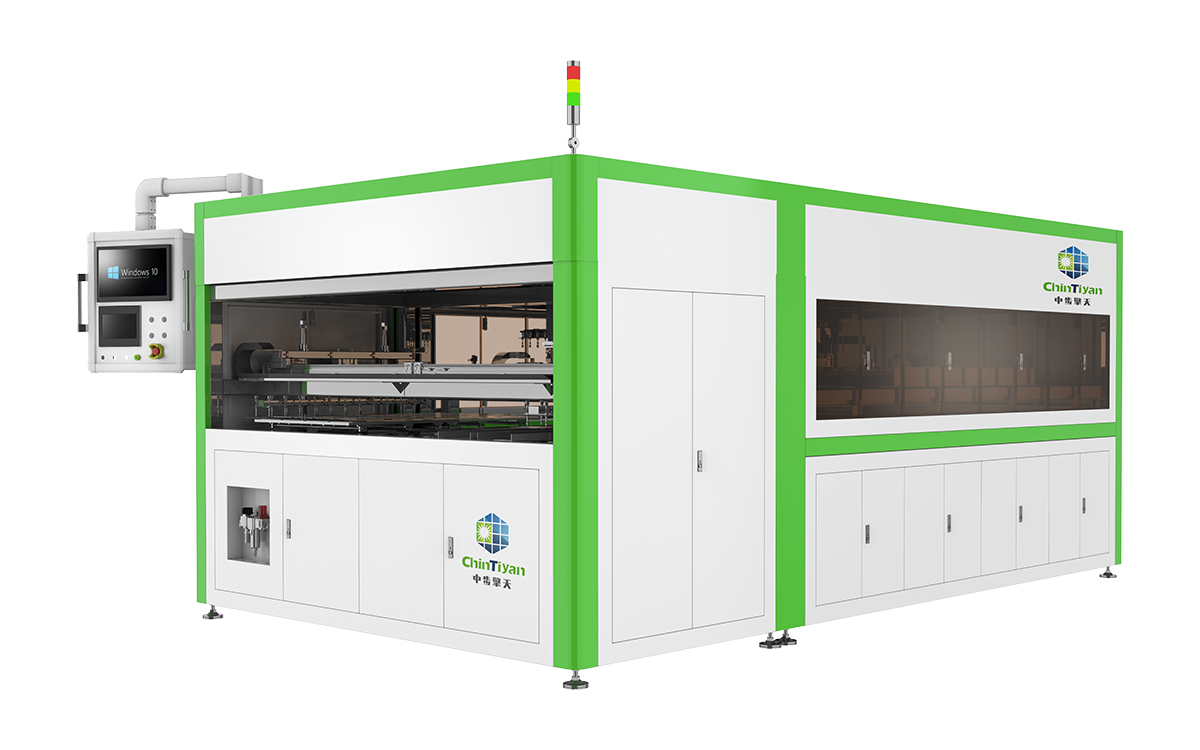

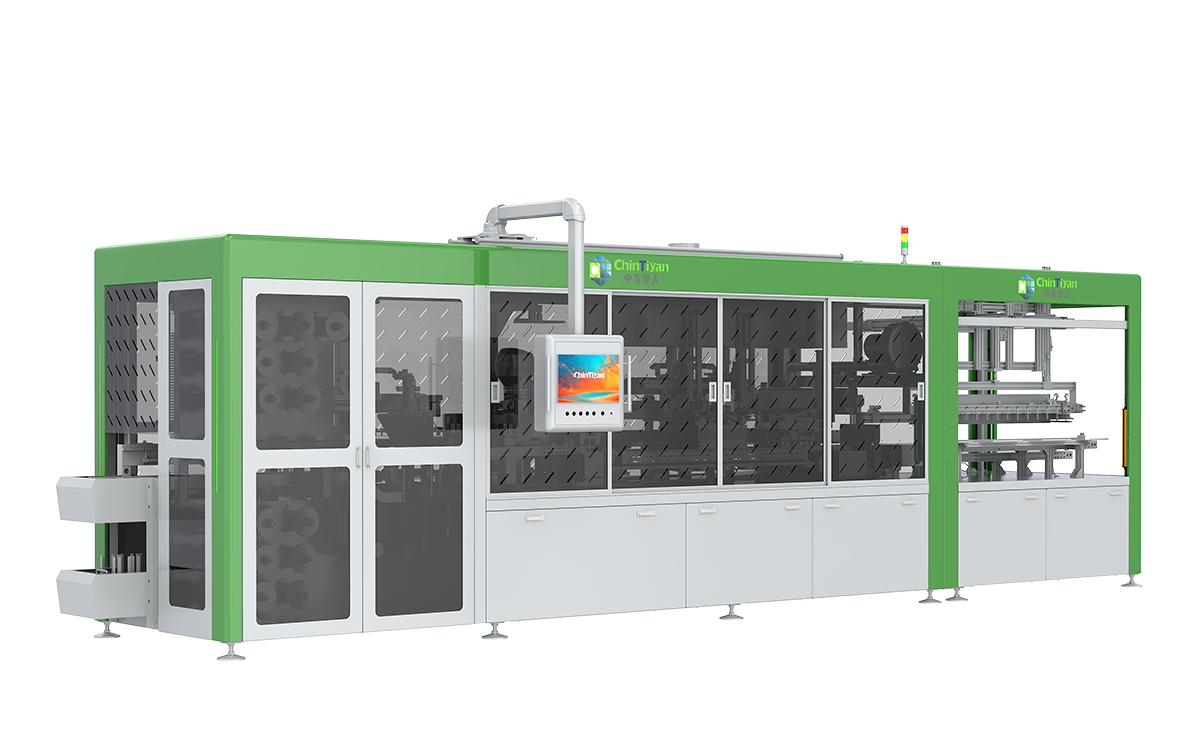

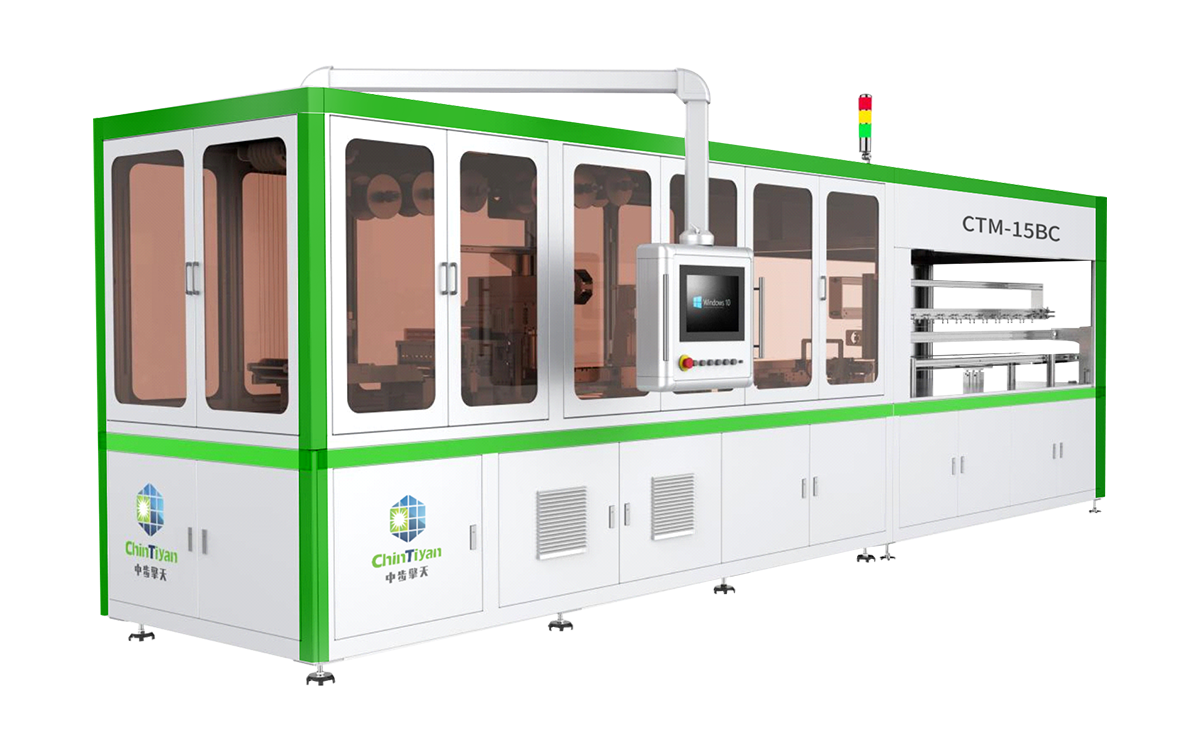

Low-Speed Stringer Machine CTM-15BC

Classification:

CTM-15BC String Welding Machine is an automated production equipment dedicated to weld BC cells to strings; compatible with 156–210mm (3BB-20BB) solar cells. It produces 156–210mm BC cell strings (including half-cell and third-cut formats).

Contact:

Details Introduction

CTM-15BC String Welding Machine is an automated production equipment dedicated to weld BC cells to strings; compatible with 156–210mm (3BB-20BB) solar cells. It produces 156–210mm BC cell strings (including half-cell and third-cut formats). Integrated with advanced automation technologies—such as PLC control, servo systems, and machine vision—it enables fully automated processing from cell loading to finished string output.

| Welding Speed Half-cell: 1000~1200 pcs/hour | Equipment Uptime Rate: ≥ 95% |

| Breakage Rate: ≤ 0.25%, A-Grade Solar Cells | Welding Method: Infrared Heating Welding |

| Meets monocrystalline cells with chamfers facing either forwards or backwards during welding | PLC + Servo Control System |

Parameter

| Equipment Model | CTM15BC Stringer |

| Uptime | ≥95% |

| Production Capacity | 166~182BC Cells: Half-cut: 1000~1200 Pieces/Hour |

| Fragmentation Rate | ≤0.25% |

| Detection Method | CCD |

| Comprehensive Positioning Precision |

Positioning Accuracy: ≤±0.1mm Angle Deviation: ≤±0.04° |

| Flux Method | Sponge soaking for soldering ribbons |

| Welding Method | Infrared welding |

| Paper Feeding Method | Automatic paper feeding with color sensor judgment |

| Cell Size | 156~210mm BC Cells and corresponding half/third-cut cells |

| Main Busbar Number | 3BB~20BB |

| Cell Thickness | 120μm~200μm |

| Max String Length | 2000mm |

| String Defect Rate | ≤3% |

| Cell Defect Detection | Capable of detecting missing corners, chipped edges, cracks, thread printing deviations, and misalignments |

| Cell Spacing | -1mm~5mm |

| Cell Spacing Precision | ±0.3mm |

| Cell Output Interface | Compatible with layout machines or standalone use |

| Cell Box Capacity | 240 small pieces of battery cells (2 AB boxes) |

| Overlap Rate | ≤15% |

| Welding Ribbon Specs | Low-temperature flat ribbon: Width: 0.6~3.0mm Thickness: 0.18~0.32mm |

| Welding Ribbon Parameter |

Solder Layer Thickness: ≥0.018±0.005mm (single-sided average) Copper Material Purity: ≥99.97% Extension Rate: ≥20% Tensile Strength: ≥150MPa |

| Power Supply |

Three-phase 380V, 50Hz Three-phase five-wire (L1/L2/L3/N/PE), Wiring specifications: 4x10mm²+1x6mm² |

| Power | Average Power: 15kW, Peak Power: 20kW |

| Air Source Requirements |

Pressure: 0.6~0.8MPa Air Consumption: ≥600L/min Inlet Pipe: 16mm soft pneumatic pipe |

|

Air Quality Standards: Max Solid Particle Size: 15μm (Level 3) Lowest Pressure Dew Point: +3°C (Level 4) Maximum Oil Mist Concentration: 5mg/m³ (Level 4) |

|

| Exhaust System |

Top Exhaust Pipe Diameter: Φ102mm Pipe Requirements: 104mm diameter Exhaust Volume: ≥300m³/h Recommended Pipe Material: PVC (due to high exhaust temperature) |

| PLC | Beckhoff Compact Industrial PC |

| HMI | User-friendly software including parameter settings, fault diagnosis, alarms, product statistics, and status records |

| MES Interface | Ethernet port reserved, supporting TCP/IP and Beckhoff ADS protocols |

Keyword:

Low-Speed Stringer Machine CTM-15BC

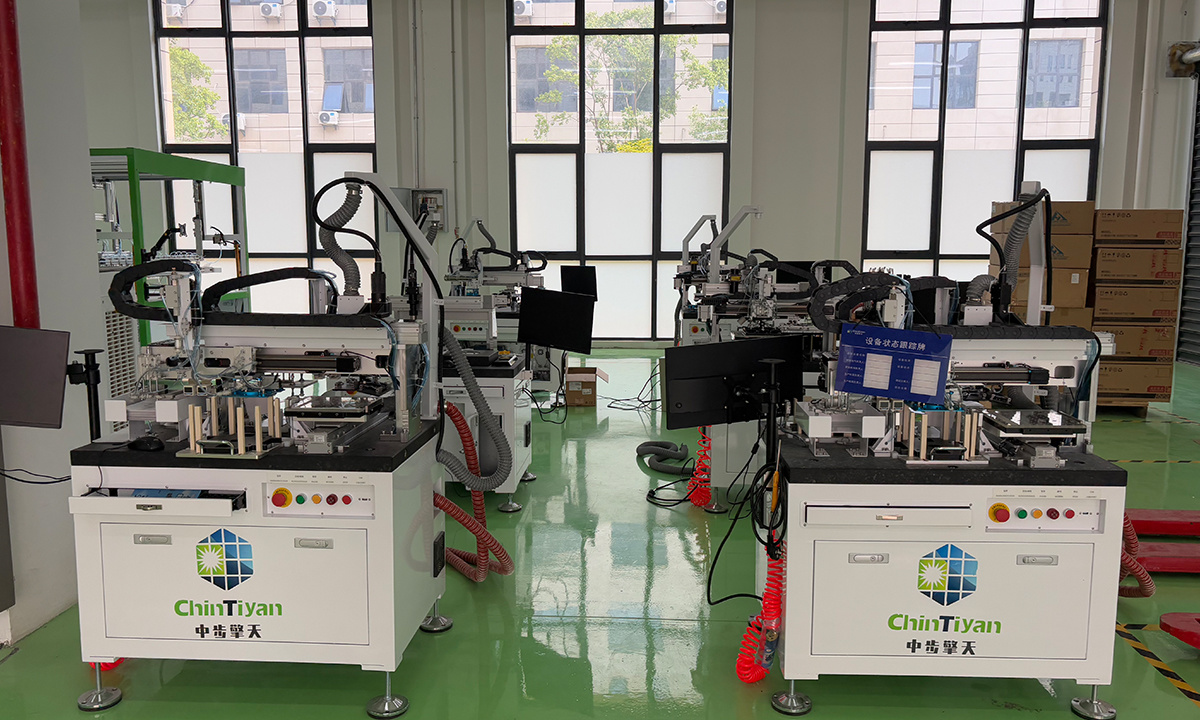

Production Strength

What is the Warranty Period of ChinTiyan New Energy?

1.One year standard warranty from the date of completion installation & commissioning for the Full/Semi-Automatic Solar PV Module Production Line, or 13 months from the date of shipment whichever is earlier.

2.For the BOM List of Raw Materials for Full/Semi-Automatic Solar Panel Production Line, the Warranty Period is usually Six Months, especially Flux, Heating Oil and some other Chemicals and Dangerous Materials.

3.Free warranty for One Year (including Labor and Material fees, excluding Man-made Damage). Any losses caused by human misuse, abuse or improper maintenance are not covered by the warranty. Maintenance fees will be charged appropriately outside the warranty period.

What are the Main Differences Between Full-Automatic and Semi-Automatic Solar PV Module Production Line?

1.For the Full-Automatic Solar PV Module Production Line, there are more Automatic Solar Machines and Equipment in the Production Line, which could surely save more labors.

2.In the Full-Automatic Solar PV Module Production Line, there are also many Automatic Conveyors and Transmission Lines, which could help to transfer the Raw Materials from one process to the next process; But in the Semi-Automatic Solar PV Module Production Line, it needs labors to carry the unfinished Solar PV Modules from one process to the next process.

What is the Payment Terms of the Purchasement in ChinTiyan?

1. Once the Clients confirm the Final Prices of all the solar making machines and equipment, ChinTiyan New energy will send the Performa Invoice (PI) to the Clients. Clients should arrange 40%T/T deposit as the Down Payment, then ChinTiyan factory will start manufacturing all the Machines and Equipment.

2. During the Manufacture Process, Clients can come to ChinTiyan factory to inspect all the Solar Machines and Equipment if required. After inspection, Clients should arrange the rest 60% Balanced Payment Before Delievery or Shipment. ChinTiyan factory start to pack all the Solar Machines and Equipment, and deliver them to Clients. If Clients could not come to China for the inspection, ChinTiyan factory could send the Videos and Photos of all the Solar Machines and Equipment for Clients as reference.

What is the Policy of Installation, Commissioning & Training Services of ChinTiyan New Energy?

1. Workers and Technical Engineers of the Purchaser can come to ChinTiyan’s factory to get the most Professional One-by-one Training.

2. ChinTiyan New Energy may also send Engineering Team to the Purchaser's factory to train their workers during operation.

3. Remote training through Internet tools like Team-Viewer, Google Meet or other instant communication software.

Related Products