High-Speed Non-Destructive

Classification:

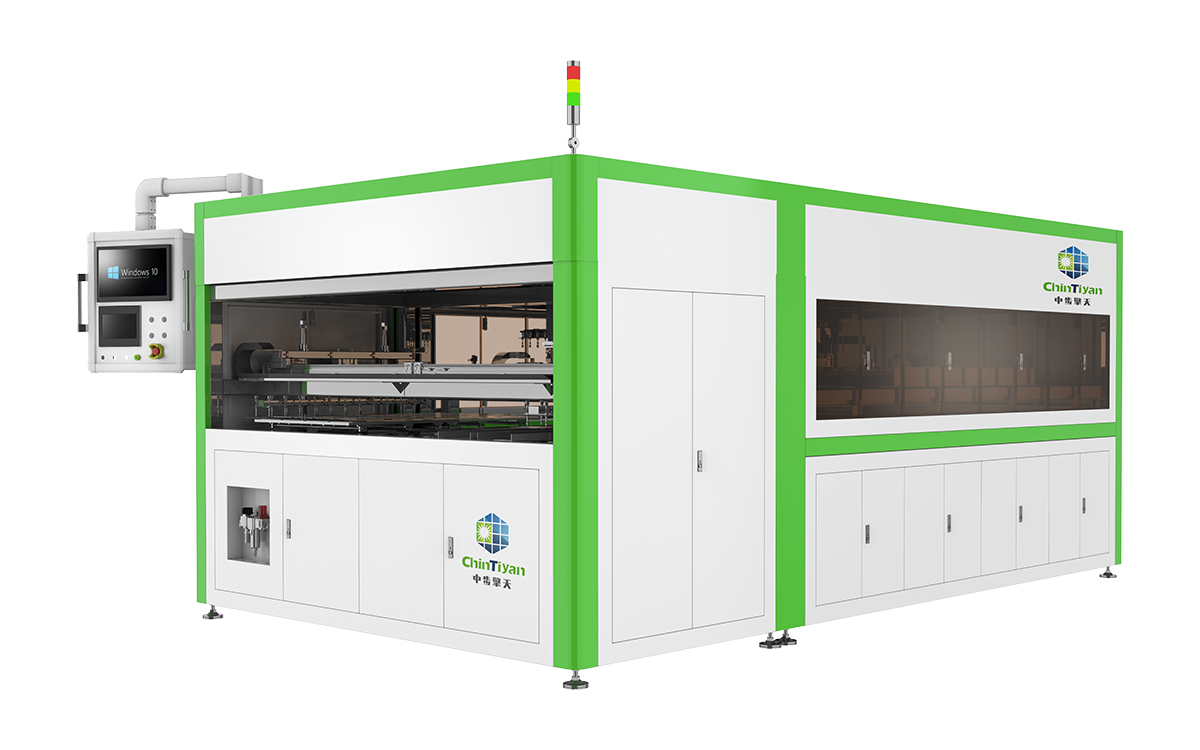

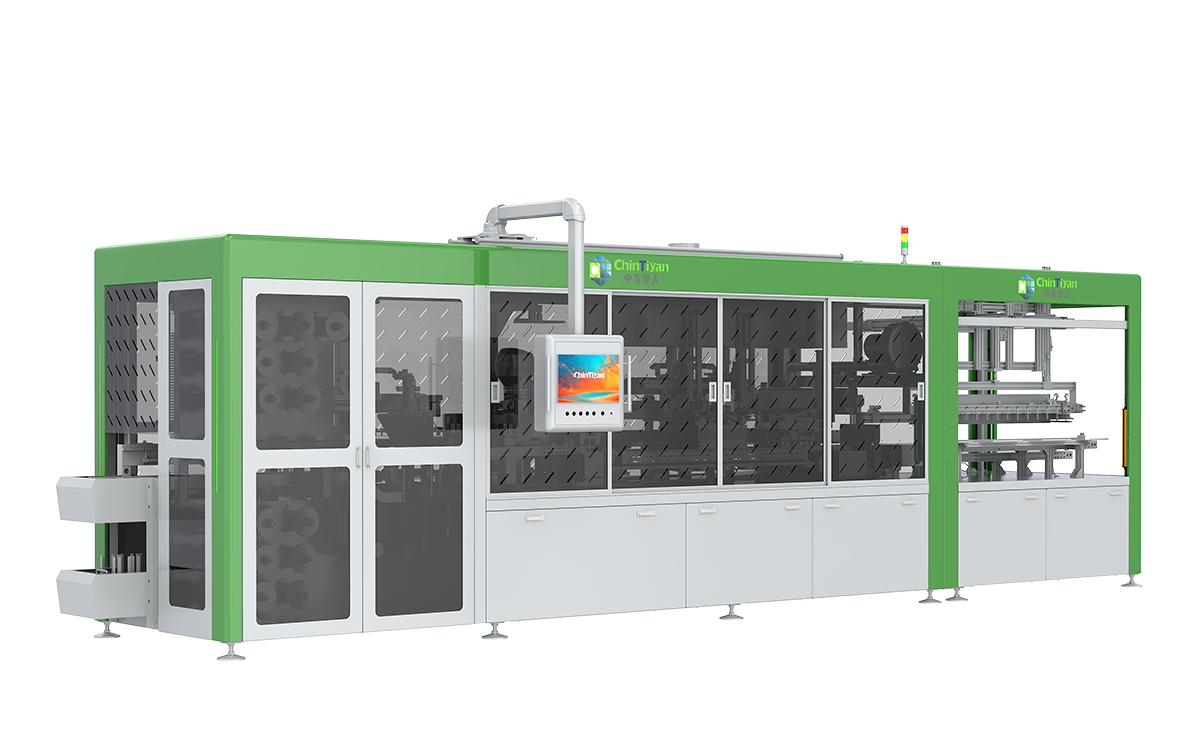

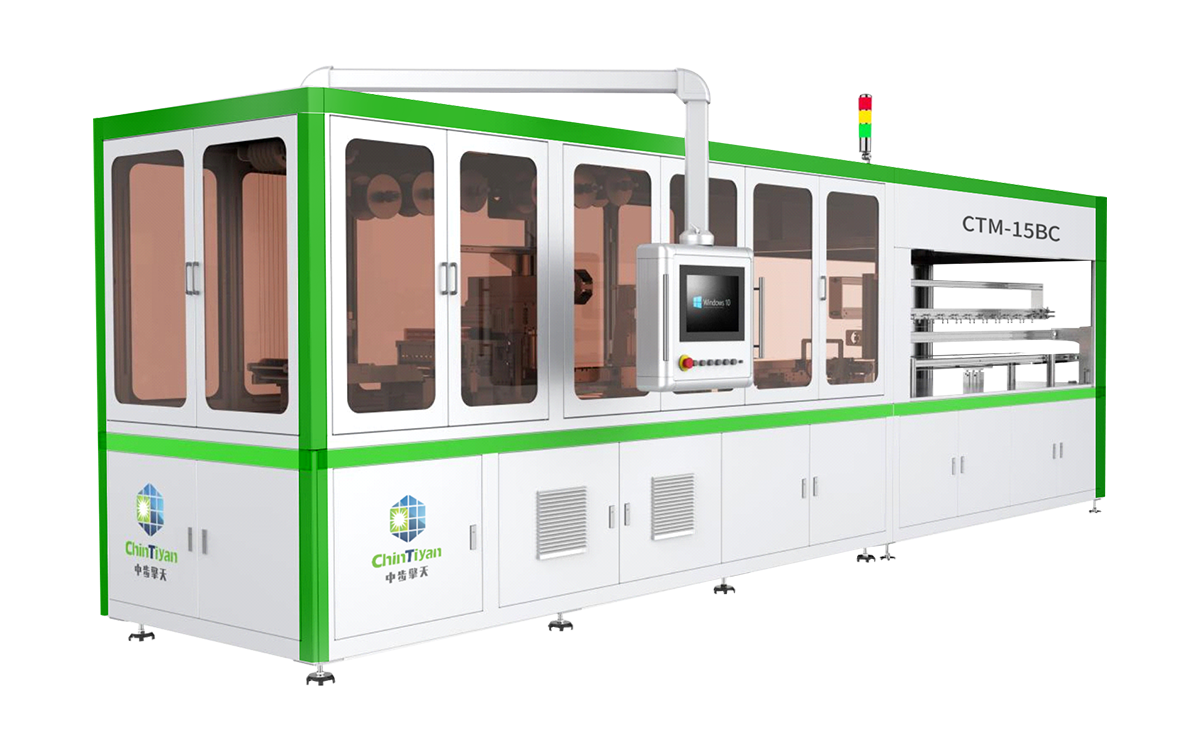

The CTC-72SBC laser slicing machine is an automated production device designed for the non-destructive cutting of cell cells. It integrates advanced automation technologies, including PLC, sensors, servo systems, laser machines, and CCD vision, to achieve a fully automatic process from paper feeding, slotting, non-destructive splitting, separation, inspection, and paper discharge. The machine is designed to handle 166-210mm cell cells, with a two-part cutting capacity of over 4800 pieces per hour. Using non-destructive cutting technology, it causes minimal damage to the cell cell surface and produces very little dust during processing, eliminating fire hazards. Non-destructive processing eliminates the need for mechanical splitting, ensuring no micro-cracks after cutting and excellent mechanical performance.

Contact:

Details Introduction

The CTC-72SBC laser slicing machine is an automated production device designed for the non-destructive cutting of cell cells. It integrates advanced automation technologies, including PLC, sensors, servo systems, laser machines, and CCD vision, to achieve a fully automatic process from paper feeding, slotting, non-destructive splitting, separation, inspection, and paper discharge. The machine is designed to handle 166-210mm cell cells, with a two-part cutting capacity of over 4800 pieces per hour. Using non-destructive cutting technology, it causes minimal damage to the cell cell surface and produces very little dust during processing, eliminating fire hazards. Non-destructive processing eliminates the need for mechanical splitting, ensuring no micro-cracks after cutting and excellent mechanical performance.

| The laser slot the neatly arranged cell, and the length of the slot is less than or equal to 2mm | The cell conveyor delivers the cell to the CCD inspection station |

| The drying system removes water from the surface of the cell | Chipping cooling system |

| The positioning accuracy is fixed, and the positioning deviation is less than ±0.05mm | The nondestructive cutting technology has very little damage to the surface of the cell |

Parameter

Equipment Parameter

| Equipment Model | CTC-72SBC High Speed Non-destructive Scribing Machine |

| Cell Size | 166 x 166~230x230mm, thickness 120~220um |

| Uptime | ≥ 95% |

| Capacity | Two pieces are more than 4800pcs/h |

| Breakage Rate | ≤0.1% |

| Speed | ≤500mm/s |

| Average Laser Power | 60 W/300-500W |

| Laser Lifetime / Warranty | Warranty 20,000 hours |

| Load and Take Paper | The separator is automatically distinguished and separated from the cell |

| Welding Method | Infrared bonding |

| Material Loading Inspection | Positioning and defect detection (crack, corner, chip, 90° flip, etc.) |

| Integrated Positioning Accuracy | Position deviation: ±0.1mm Angle deviation: ±0.04° |

| Welding Tension | The welding tension is greater than or equal to 2.0N(0.6mm flat soldering strip, and the cell plate is brushed with solder paste. Each grid line is allowed to have no more than one point <2.0N); |

| (0.6mm wide flat welding strip) | |

| Cell Positioning Accuracy | Position accuracy: X, Y≤±0.1mm, Angle less than or equal to 0.04° |

| Defect Detection | It can detect defects such as missing corners, broken edges, cracking, and deviation of screen printing |

| Inter-cell Gap | -1mm to 5mm |

| Gap Accuracy | ±0.3mm |

| Starting Welding Position | Set it as needed |

| Magazine Capacity | 360 small cell packs |

| String EL test | Welding defects such as false welding and hidden cracks |

| String Reject Rate | ≤3% |

| Overlap/Flip Rate | ≤15% |

| Ribbon Specifications | Welding wire types: φ0.29 to φ0.45mm, size tolerance ±0.01 yield strength: 70~80MPa; tensile strength: ϗ150MPa elongation: ϗ25% |

| Ribbon Parameters | Average thickness of one side of tin layer: 0.018±0.005mm or more purity of copper substrate: 99.97% or more elongation: 20% or more tensile strength: 150MPa or more yield strength: 70MPa or less |

| Ribbon Spool Specifications | The inner diameter of the welding strip disc I-beam is 16mm or 20mm, the outer diameter is less than or equal to 180mm, and the width is less than or equal to 160mm |

| Material Inspection | Check for cracks, broken edges and corners, and large pieces |

| Power Supply | Three-phase 380V,50Hz three-phase five-wire (L1/L2/L3/N/PE), incoming line specification 4x16mm²+1x10mm² |

| Power | The average power is 40kW and the peak power is 60kW |

| Laser Chiller Unit | Cooling water: 20 L; pure water, change regularly |

| Coolant Water for Wafer Cleaving System | Deionized water, or pure water |

| Air Supply | Pressure 0.6-0.8Mpa; gas consumption: more than 1200L/min; the intake pipe is filled with two φ16mm hoses at the same time |

| Air quality requirements for compressed air: maximum solid particle size: 15μm (grade 3); minimum pressure dew point: +3℃ (grade 4); maximum oil mist concentration: 5mg/m3 (grade 4) | |

| Exhaust System | The diameter of the top exhaust pipe is Φ102mm, and the pipe diameter is required to be 104mm; the comprehensive exhaust flow rate is greater than 600m³/h; the exhaust temperature is high, and it is recommended to use PVC pipe for the exhaust pipe |

| PLC | Befre compact industrial PC |

| HMI | Yikong sky local computer software includes parameter setting, fault diagnosis, alarm, product statistics, status record and so on. |

| MES Interface | Reserve Ethernet port, support TCP/Ip and Befu ADS protocol |

Keyword:

High-Speed Non-Destructive

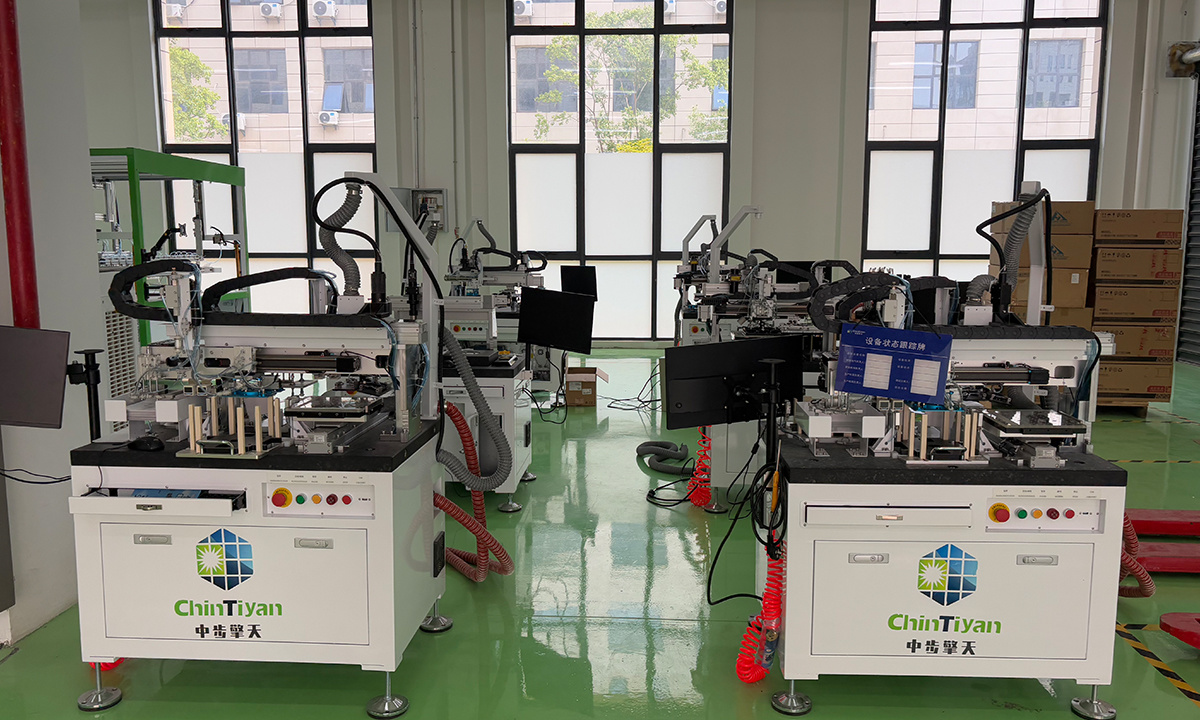

Production Strength

What is the Warranty Period of ChinTiyan New Energy?

1.One year standard warranty from the date of completion installation & commissioning for the Full/Semi-Automatic Solar PV Module Production Line, or 13 months from the date of shipment whichever is earlier.

2.For the BOM List of Raw Materials for Full/Semi-Automatic Solar Panel Production Line, the Warranty Period is usually Six Months, especially Flux, Heating Oil and some other Chemicals and Dangerous Materials.

3.Free warranty for One Year (including Labor and Material fees, excluding Man-made Damage). Any losses caused by human misuse, abuse or improper maintenance are not covered by the warranty. Maintenance fees will be charged appropriately outside the warranty period.

What are the Main Differences Between Full-Automatic and Semi-Automatic Solar PV Module Production Line?

1.For the Full-Automatic Solar PV Module Production Line, there are more Automatic Solar Machines and Equipment in the Production Line, which could surely save more labors.

2.In the Full-Automatic Solar PV Module Production Line, there are also many Automatic Conveyors and Transmission Lines, which could help to transfer the Raw Materials from one process to the next process; But in the Semi-Automatic Solar PV Module Production Line, it needs labors to carry the unfinished Solar PV Modules from one process to the next process.

What is the Payment Terms of the Purchasement in ChinTiyan?

1. Once the Clients confirm the Final Prices of all the solar making machines and equipment, ChinTiyan New energy will send the Performa Invoice (PI) to the Clients. Clients should arrange 40%T/T deposit as the Down Payment, then ChinTiyan factory will start manufacturing all the Machines and Equipment.

2. During the Manufacture Process, Clients can come to ChinTiyan factory to inspect all the Solar Machines and Equipment if required. After inspection, Clients should arrange the rest 60% Balanced Payment Before Delievery or Shipment. ChinTiyan factory start to pack all the Solar Machines and Equipment, and deliver them to Clients. If Clients could not come to China for the inspection, ChinTiyan factory could send the Videos and Photos of all the Solar Machines and Equipment for Clients as reference.

What is the Policy of Installation, Commissioning & Training Services of ChinTiyan New Energy?

1. Workers and Technical Engineers of the Purchaser can come to ChinTiyan’s factory to get the most Professional One-by-one Training.

2. ChinTiyan New Energy may also send Engineering Team to the Purchaser's factory to train their workers during operation.

3. Remote training through Internet tools like Team-Viewer, Google Meet or other instant communication software.

Related Products