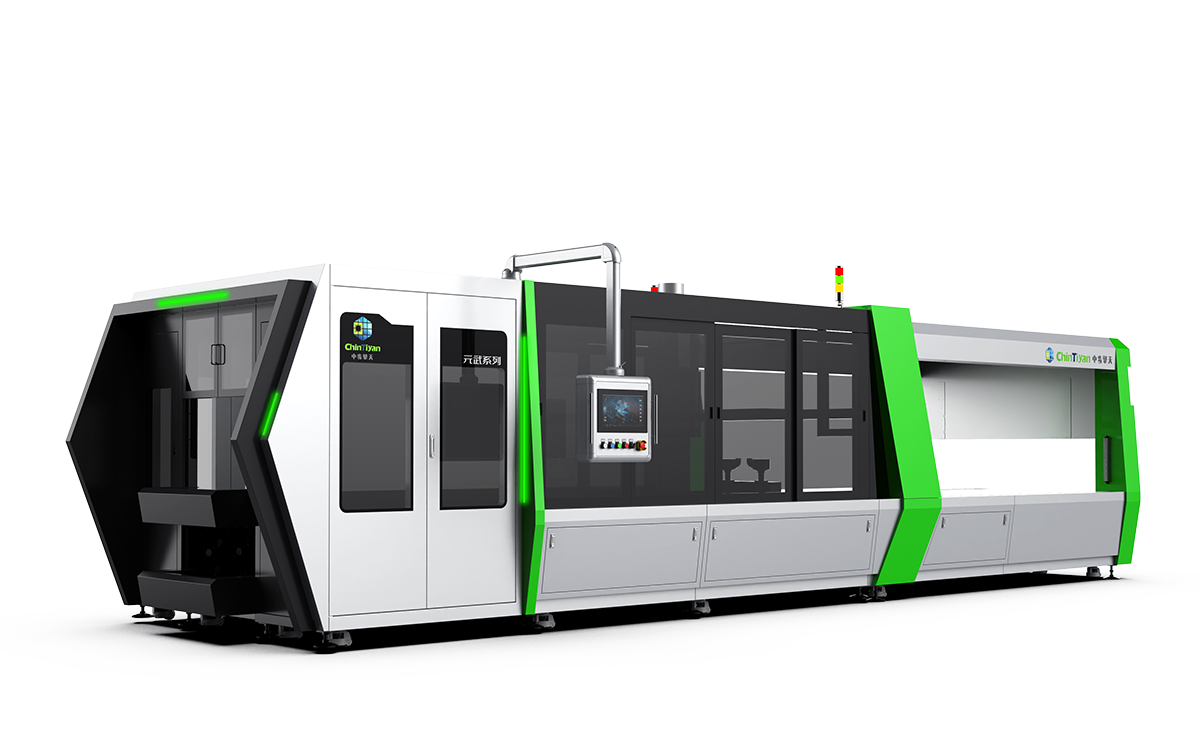

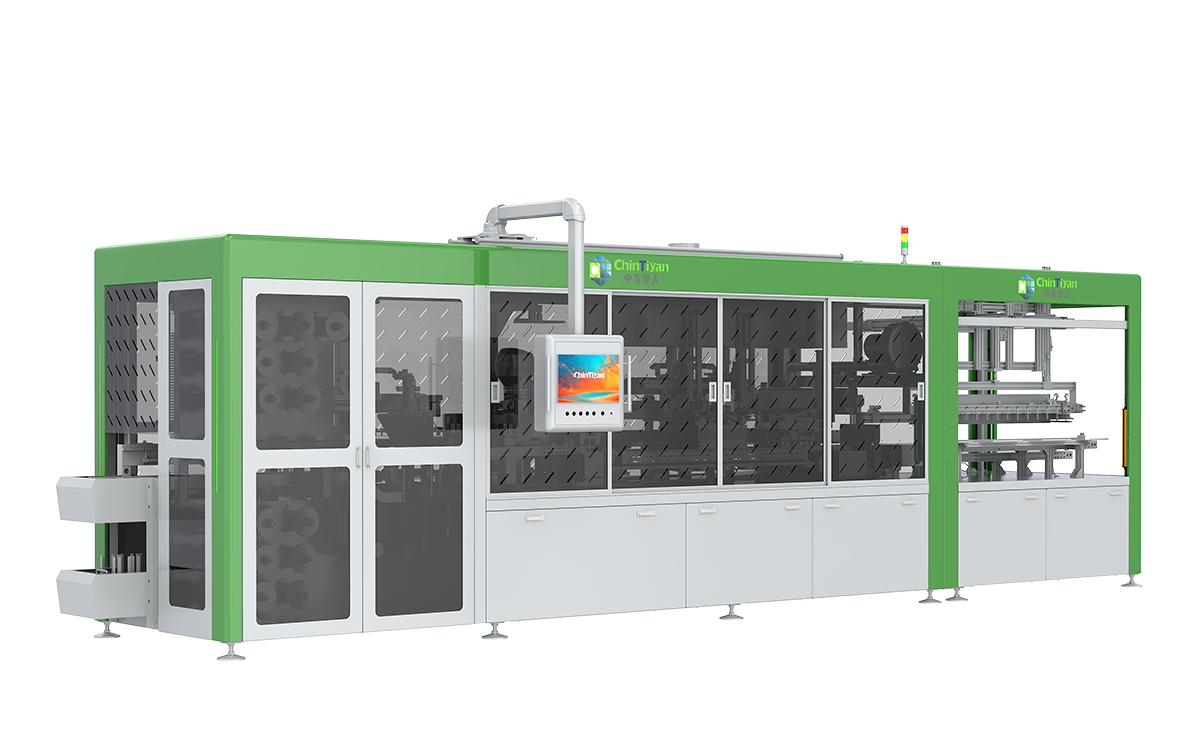

Bussing Machine

Classification:

1. Solar Panel Making Machine 2. Compatible with cells size: 156-210mm 3. Adjustable string spacing:2-6mm 4. Production Capacity:16s/module 5. With 9 camera positioning and re-aligning each strings, before busbar welding.

Contact:

Details Introduction

Bussing Machine

Suitable for solar panel production line in solar panel factories

The main function of the equipment is to separate the battery string from the glass, lift the battery string with the crane to a certain height, and then suspend the welding of the head, middle and tail of the bus bar of the in-line version module;

It has the function of rolling bus bar for belt and bending U and L leads upward.

Parameter

| Product Model | CT-HLH-200 |

| Beats | ≤18S |

| Activation rate | 99% or higher |

| Overall yield | ≥99%(according to the component unit, the componentlayout accuracy of the inflow bushing belt weldingmachine should be within ±0.5mm) |

| Fragmentation rate | < 0.02%(in pieces) |

| Maximum compatible component size | 1650*900-2500*1500mm |

| Compatible battery size(mm) | Compatible 156-210mm |

| Compatible with number of grid wire roots | Compatible with 5-15 grids |

| Power supply | Three-phase five-wire 380V/220V 50/60Hz |

| Power | Peak 40KW Average about 20KW |

| Air Supply | Pressure 0.6-0.8MPa flow 2000L/min |

| Machine size | 5220mmX2570mmX2450mm |

| Alarm device | Tri-color light + buzzer |

| Deviation correction | 9 camera visual positioning |

| Positioning mechanism | Electric cylinder/servo module |

| Number of anchor points | ≥5 points |

| Positioning method | Mechanical positioning |

| Feeding method | Roll loading, automatic cutting, bending |

| Roll size | Axle hole 20-25mm, outer diameter < 210mm |

| Roll load bearing | ≤13KG |

| Compatible bus tape width | Factory supporting 4mm, 6mm |

| Compatible with bus tape thickness | 0.18 mm to 0.4 mm |

| Cutting accuracy | 0.5 mm or less |

| How the lead is made | Bend straight up |

| Lead Angle and deviation | 90。 Deviation of 2 to 3。 |

| Handling method | Servo motor + vacuum adsorption |

| Positioning mode | Mechanical positioning + vacuum adsorption |

| Positioning accuracy | Less than 0.5mm |

| Distance from bus bar to battery | 2-10mm adjustable |

| Busbar overweld strip length | ≤2mm (length error) |

| Head life | ≥1 year |

| Welding head replacement time | ≤60min |

| Mode of operation | Servo motor |

| Cooling method | Air cooling |

| Welding method | Electromagnetic induction welding |

| Number of welding heads | 18 |

| Welding head control method | Current control/time control |

| Welding heating time | ≤2s |

| Welding temperature control accuracy | ± 5 ℃ |

| Welding tension | Weld band welding force ≥5N/mm (bus bar and weld band) |

| Weld appearance | Molten tin full |

| Welding contact area | 80% or higher |

| Scar size | ≥(4*4)mm2 |

| Control systems | PC+PLC (Reserve 5% of I/O points) |

| Communication interface | Meet MES interconnection requirements |

Keyword:

Bussing Machine

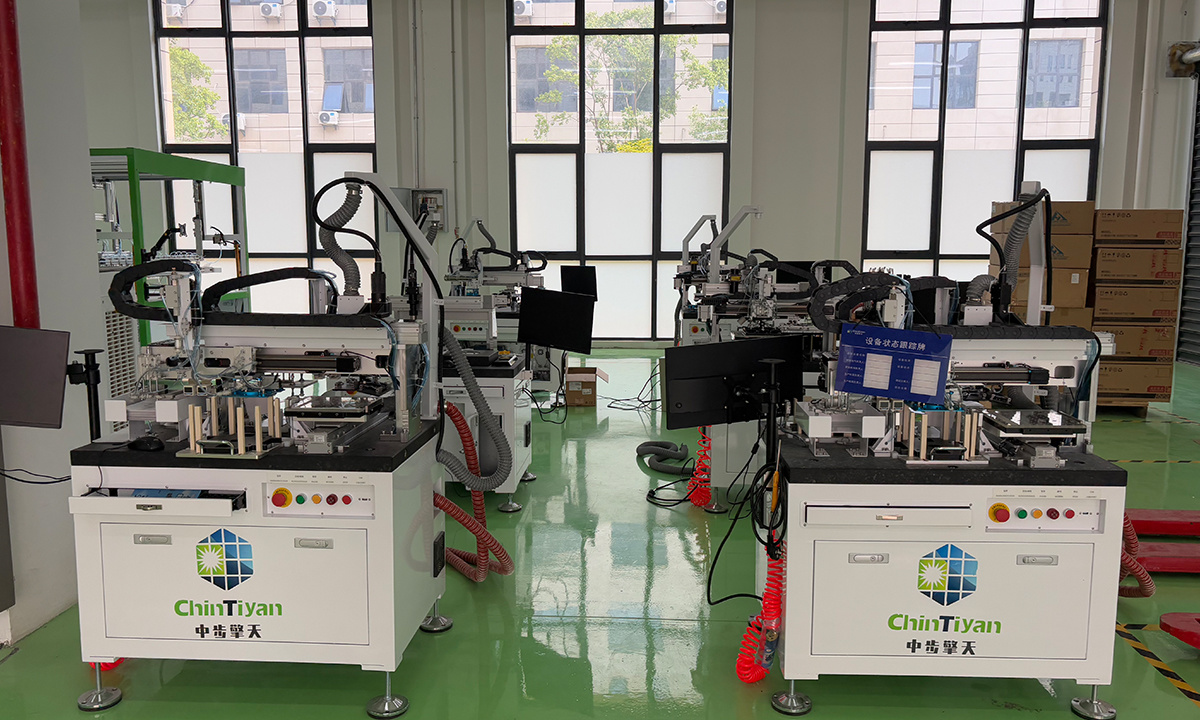

Production Strength

Is BC technology the Future?

BC (Back Contact) technology is undoubtedly a key direction for next-generation high-efficiency PV modules. Its busbar-free front side offers not only superior aesthetics but also significantly reduces shading, leading to higher light absorption and increased power output. Rather than simply declaring BC as the only future,In fact, BC is a platform technology that can be combined with techniques such as Topcon HJT and perovskite tandem cells to squeeze out the last drop of efficiency gains.

Therefore, we believe BC technology will remain at the forefront of the upcoming technological transformation, making now the opportune moment to invest in BC.

Why We Say "NO" to Fast Quotes ?

Whilst we offer some of the most competitive pricing in the industry, we firmly believe that a well-designed production line holds far greater value than the mere pursuit of low cost. A single quotation cannot suit all. Only after gathering the necessary information and undertaking a bespoke design tailored to each product's characteristics and process requirements can we provide a quotation truly worthy of discussion.

What Information is Required to Establish a Production Line?

This is straightforward.

Firstly, we need to understand the type of modules you wish to manufacture: conventional or flexible, large-format or small-format, and whether any specialised processes are required. Secondly, we require details of your production line capacity requirements – be it a 50MW manual line or a 2GW fully automated dark factory.

Finally, if you have already constructed a facility for your project, we need to know the dimensions of the building; a CAD file would be most helpful if available. Naturally, should you be unfamiliar with photovoltaic module manufacturing, there is no need for concern. We shall recommend the most suitable production line design based on your market requirements.

What is Our Collaboration Process?

We consider after-sales service the beginning of a long-term partnership, not the end of a transaction. We provide a full-spectrum "service ecosystem" that covers the entire journey from initial discussion to stable mass production.

1.Collaboration and Delivery Process

Requirement Confirmation & Technical Discussion: We start with in-depth communication to clarify product specifications, capacity goals, and technical requirements, providing a preliminary technical solution.

2.Plan Finalization & Contract Signing: Upon reaching a technical consensus, we proceed to draft and sign the commercial contract and technical agreement.

3.Production Line Construction & Equipment Manufacturing: In parallel, you can proceed with plant construction/renovation, utility preparation, and team building. We simultaneously conduct lean manufacturing and assembly of the equipment.

4.Factory Acceptance Test (FAT): After assembly and debugging, we warmly welcome you to our facility for a pre-acceptance test to verify equipment performance firsthand.

5.Maritime Logistics & On-site Installation: Following FAT, equipment is shipped via maritime logistics to your plant. Our engineer team will be on-site to guide installation and positioning.

6.Commissioning & Site Acceptance (SAT): After installation, our engineers perform precise commissioning and complete the final Site Acceptance Test, ensuring the line meets all agreed performance metrics.

7.Training & Guided Production: We provide comprehensive operation and maintenance training, and guide you through small-batch trial production to ensure your team can operate the line independently.

8.Long-term Support & Continuous Improvement: Our comprehensive long-term after-sales service begins after mass production, including remote support, spare parts supply, periodic visits, and technical upgrade services, ensuring your sustained production and future growth.

Related Products