Working Principle and Purpose of the BC Stringer Machine for PV Modules

Release time:2025-09-05

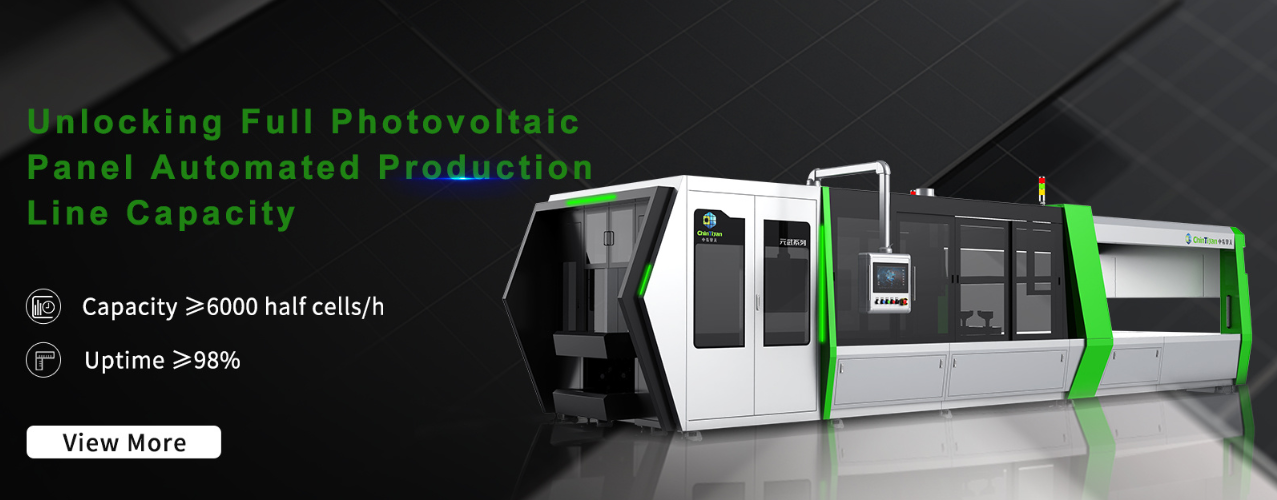

In the field of photovoltaic (PV) cell production, high-efficiency and precision equipment is the key to ensuring product quality and production speed. The BC stringer machine is specially developed for BC-type cells, representing cutting-edge technology while setting new benchmarks in both production efficiency and accuracy. Taking the self-developed high-speed BC stringer machine CTM-60BC from ChinTiyan as an example, what exactly are its working principles and applications?

I. Working Principle of the CTM-60BC String Welding Machine

1. Dual-Line Independent Control Mode

The A and B sides can operate independently, meeting different production demands simultaneously. This design provides higher flexibility and versatility.

2. Adaptive Guide Groove System

The unique guide groove tracking system allows multiple cells to be soldered simultaneously, greatly improving production efficiency.

3. Intelligent “Basket-Style” Feeding System

Combined with high-speed visual inspection and positioning, as well as a high-speed robotic arm and linear motor for pick-and-place operations, the system achieves high-speed, high-precision, and highly stable production.

4. Precise Temperature Control System

To ensure more stable soldering quality, the high-speed BC stringer machine is equipped with a precise temperature control system. This keeps temperature zone uniformity within ±5 °C, perfectly suited to the low-temperature soldering characteristics of BC cells.

II. Main Applications of the CTM-60BC Stringer Machine

•High-Speed Production of BC Solar Cells

Specifically designed for BC-type cells, its primary purpose is to solder BC cells into strings at high speed and efficiency.

•Modular Design for Customized Integration

The CTM-60BC adopts a modular design, which enables seamless integration with both upstream and downstream equipment, meeting the customized requirements of different production lines.

•Improving Production Efficiency

In today’s fiercely competitive PV cell market, enhancing production efficiency directly impacts a company’s survival. With a development throughput of 7,200 cells/hour and an expected stable production capacity of 6,000 cells/hour, the CTM-60BC significantly boosts efficiency and output for manufacturers.

Conclusion

As the industrialization of BC solar cells accelerates, the demand for related equipment is experiencing rapid growth. As a core device on the PV module production line, the BC stringer machine plays a critical role in ensuring process quality and production yield.

ChinTiyan- BC stringer machine, with its advanced working principles and outstanding performance, is bringing revolutionary transformation to the PV manufacturing industry, offering customers a one-stop solution.

Next Page

Next Page