Precision Scribing Machines: Driving the Next Leap in Solar Manufacturing

Release time:2025-09-17

In the accelerating global transition toward carbon neutrality, the efficiency and reliability of photovoltaic (PV) module manufacturing have become decisive factors in the industry’s competitiveness. Among the core technologies shaping the future of solar production, the scribing machine—often referred to as the “scalpel” of solar cells—has emerged as one of the most critical innovations.

1. The Role of Scribing Machines in Solar Manufacturing

Scribing machines are essential in dividing and structuring solar cells with micron-level accuracy. By using laser or mechanical cutting techniques, these machines enable manufacturers to optimize cell efficiency while minimizing material loss. Advanced models now integrate blue-laser technology (around 450 nm wavelength), which significantly reduces the heat-affected zone to less than 15μm. This ensures that delicate wafers—especially ultra-thin cells used in TOPCon and heterojunction (HJT) technologies—can be processed with a fragmentation rate of below 0.05%.

Furthermore, the introduction of non-destructive scribing processes has redefined throughput benchmarks. Cutting speeds of more than 7,000 cells per hour are increasingly common, representing efficiency gains of up to 40% compared to conventional methods. These breakthroughs directly translate into higher production yields and more cost-effective solar modules.

2. From High Precision to Intelligent Manufacturing

Today’s leading scribing machines are no longer just precision cutters—they are evolving into intelligent manufacturing platforms. Integrated vision systems enable positioning accuracy within ±0.05 mm, allowing for consistent quality in mass production. Some models even combine AI-powered defect detection, identifying microcracks or corner flaws in real time to ensure maximum reliability across production batches.

As solar technologies shift toward larger wafer formats (166–210 mm and beyond), flexibility has also become crucial. Modern scribing machines are designed to adapt to multiple wafer sizes and thicknesses, making them indispensable for manufacturers seeking long-term scalability.

3. Our Company’s Contribution

At ChinTiyan New Energy, we have been at the forefront of delivering next-generation scribing solutions. Our portfolio covers both high-speed and low-speed models, supporting diverse production needs from BC (Back Contact) technologies to mainstream cell architectures. Whether customers require non-destructive scribing for ultra-thin wafers or cost-efficient conventional cutting, our equipment is engineered to ensure precision, stability, and productivity.

By combining deep expertise in photovoltaic equipment manufacturing with continuous R&D investment, ChinTiyan New Energy is committed to helping global partners achieve higher efficiency, lower costs, and more sustainable solar production.

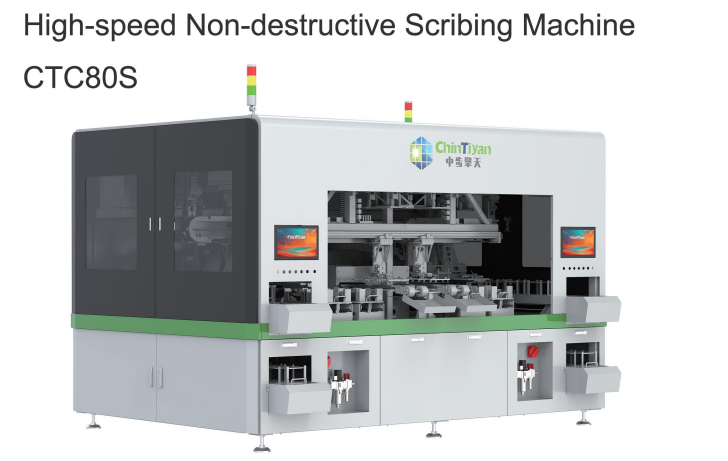

4. Equipment Spotlight

The CTC-80S Laser Scribing Machine is an automated production device for non-destructive cutting of crystalline silicon cells. It integrates advanced automation technologies such as PLC, sensors, servos, lasers, and CCD vision, enabling fully automated processing from cell loading, grooving, non-destructive scribing, separation, inspection, to unloading. Designed for cell sizes of 156-230mm, it achieves half-cell cutting at speeds of >7200 PCS/H.

This machine uses non-destructive cutting technology, minimizing surface damage and generating very little dust, eliminating fire risk concerns. The non-destructive process does not require mechanical breaking, ensuring no micro-cracks and excellent mechanical performance post-cutting.

Previous Page

Previous Page

Related News